Toyota Highlander Service Manual: Overhaul

1. REMOVE GENERATOR PULLEY

SST 09820-63010 (09820-06010, 09820-06020)

HINT:

(a) Hold SST (1-A) with a torque wrench, and tighten SST (1-B) clockwise to the specified torque.

Torque: 39 NVm (400 kgfVcm, 29 ftVlbf)

NOTICE: Check that SST is secured to the rotor shaft.

(b) Mount SST (2) in a vise.

(c) Insert SST (1-A, B) into SST (2), and attach the pulley nut to SST (2).

(d) To loosen the pulley nut, turn SST (1-A) in the direction shown in the illustration.

NOTICE: To prevent damage to the rotor shaft, do not loosen the pulley nut more than one-half turn.

(e) Remove the generator from SST (2).

(f) Turn SST (1-B) and remove SST (1-A, B).

(g) Remove the pulley nut and pulley.

2. REMOVE GENERATOR REAR END COVER

(a) Place the generator on the pulley.

(b) Remove the 3 nuts and rear end cover.

3. REMOVE TERMINAL INSULATOR

(a) Remove the terminal insulator from the rectifier end frame.

4. REMOVE GENERATOR BRUSH HOLDER ASSY

(a) 100 A: Remove the 2 screws and brush holder.

(b) 130 A: Remove the brush holder.

- Remove the plate seal.

- Remove the 2 screws and brush holder.

- Remove the plate seal.

5. REMOVE GENERATOR COIL ASSY

(a) Remove the 4 bolts.

(b) Using SST, remove the rectifier end frame.

SST 09950- 40011 (09951- 04020, 09952- 04010, 09953- 04020, 09954- 04010, 09955- 04071, 09957-04010, 09958-04011)

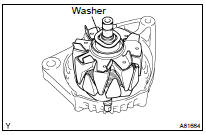

6. REMOVE GENERATOR ROTOR ASSY

(a) Remove the washer and rotor.

7. INSPECT GENERATOR BRUSH HOLDER ASSY

(a) 100 A: Using a vernier caliper, measure the exposed brush length.

Standard exposed brush length: 10.5 mm (0.413 in.) Minimum exposed brush length: 4.5 mm (0.177 in.)

If the exposed brush length is less than the minimum, replace the brush holder assy.

(b) 130 A: Using a vernier caliper, measure the exposed brush length.

Standard exposed brush length: 10.5 mm (0.413 in.) Minimum exposed brush length: 4.5 mm (0.177 in.)

If the exposed brush length is less than the minimum, replace the brush holder assy.

8. INSPECT GENERATOR ROTOR ASSY

(a) Check that the bearing is not rough or worn.

100 A: If necessary, replace the rotor assy.

130 A: If necessary, replace the rotor bearing.

(b) Check if the rotor has open circuit.

- Measure the resistance between the slip ring.

Resistance: 2.3 to 2.7 W at 20 C (68 F)

If the resistance is not as specified, replace the rotor assy.

(c) Check the rotor for ground.

- Measure the resistance between the slip ring and

rotor core.

Standard: 1 MW or higher

If the resistance is not as specified, replace the rotor assy.

(d) Check that the slip rings are not rough or scored.

If rough or scored, replace the rotor assy.

(e) Using vernier calipers, measure the slip ring diameter.

Standard diameter: 14.2 to 14.4 mm (0.559 to 0.567 in.) Minimum diameter: 14.0 mm (0.551 in.)

If the diameter is less than the minimum, replace the rotor assy.

9. 130 A: REMOVE GENERATOR ROTOR BEARING

(a) Using SST, remove the bearing cover (outside) and bearing.

SST 09820-00021

NOTICE: Be careful not to damage the fan.

(b) Remove the bearing cover (inside).

10. 130 A: INSTALL GENERATOR ROTOR BEARING

(a) Place the generator rotor on the generator pulley.

(b) Install the bearing cover (inside).

(c) Using SST and a press, press in a new bearing.

SST 09820-00031

(d) Using SST, push in the bearing cover (outside).

SST 09285-76010

11. INSPECT GENERATOR DRIVE END FRAME BEARING

(a) Check that the bearing is not rough or worn.

If necessary, replace the bearing.

12. REMOVE GENERATOR DRIVE END FRAME BEARING

(a) Remove the 4 screws and retainer plate.

(b) Using SST and a wooden block, tap out the bearing.

SST 09950- 60010 (09951- 00250), 09950- 70010 (09951-07100)

13. INSTALL GENERATOR DRIVE END FRAME BEARING

(a) Using SST and a press, press in a new bearing.

SST 09950- 60010 (09951- 00470), 09950- 70010 (09951-07100)

(b) Install the retainer plate with the 4 screws.

Torque: 2.3 NVm (23 kgfVcm, 20 in.Vlbf)

14. INSTALL GENERATOR ROTOR ASSY

(a) Place the generator drive end frame on the pulley.

(b) Install the rotor and washer.

15. INSTALL GENERATOR RECTIFIER END FRAME

(a) 100 A: Using deep socket wrench 21 and a press, press in the coil carefully.

(b) 130 A: Using deep socket wrench 20 and a press, press in the coil carefully.

(c) Tighten the 4 bolts.

Torque: 5.8 NVm (59 kgfVcm, 51 in.Vlbf)

16. INSTALL GENERATOR BRUSH HOLDER ASSY

(a) 100 A: Install the brush holder.

- While pushing the 2 brushes to inside the brush holder, insert a pin (f1.0 mm (0.039 in.)) into the brush holder hole.

- Install the brush holder with the 2 screws.

Torque: 1.8 NVm (18 kgfVcm, 16 in.Vlbf)

- Pull out the pin (f1.0 mm (0.039 in.)) from the brush holder.

(b) 130 A: Install the brush holder

- Install the plate seal (inside).

- Place the brush holder with the pin facing upward.

NOTICE: Be careful of the generator brush holder installing direction.

- Tighten the 2 screws.

Torque: 1.8 NVm (18 kgfVcm, 16 in.Vlbf)

- Align the pins of the brush holder with the holes of the plate seal (outside), and install the plate seal (outside).

17. INSTALL TERMINAL INSULATOR

(a) Install the terminal insulator.

NOTICE: pay attention to the mounting direction of the terminal insulator.

18. INSTALL GENERATOR REAR END COVER

(a) Install the rear end cover with the 3 nuts.

Torque: 4.6 NVm (47 kgfVcm, 41 in.Vlbf)

19. INSTALL GENERATOR PULLEY

SST 09820-63010 (09820-06010, 09820-06020)

HINT:

(a) Install the pulley to the rotor shaft by tightening the generator pulley nut by hand.

(b) Hold SST (1-A) with a torque wrench, and tighten SST (1-B) clockwise with the specified torque.

Torque: 39 NVm (400 kgfVcm, 29 ftVlbf)

NOTICE: Check that SST is secured to the rotor shaft.

(c) Mount SST (2) in a vise.

(d) Insert SST (1-A) and (B) into SST (2), and attach the generator pulley nut to SST (2)

(e) Tighten the pulley nut by turning SST (1-A) in the direction shown in the illustration.

Torque: 111 NVm (1,125 kgfVcm, 81 ftVlbf) (f) Remove the generator from SST (2).

(g) Turn SST (1-B), and remove SST (1-A), (B).

(h) Turn the pulley, and check that the pulley moves smoothly.

Replacement

Replacement

1. REMOVE V BELT (See page 14-5 )

2. REMOVE GENERATOR ASSY

(a) Remove the bolt, and disconnect the wire clip on the wire

connectors from the generator.

(b) Disconnect the wire clamp from the w ...

Starting system (3MZ-FE)

Starting system (3MZ-FE)

INSPECTION

1. INSPECT STARTER ASSY

NOTICE:

These tests must be performed within 3 to 5 seconds to

avoid burning out the coil.

(a) Do the pull-in test.

Disconnect the lead wire from ...

More about Toyota Highlander:

Symptom simulation

HINT:

The most difficult case in troubleshooting is when no problem symptoms occur. In

such cases, a thorough

customer problem analysis must be carried out. A simulation of the same or

similar conditions and environment

in which the problem occurred in the customer's vehicle should be carried ...