Toyota Highlander Service Manual: On-vehicle inspection

1. INSPECT AIR-FUEL RATIO COMPENSATION SYSTEM

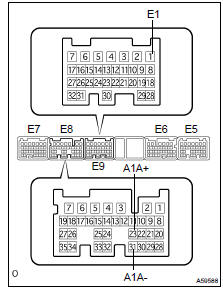

(a) Measure the voltage between the terminals of the ECM connectors.

Standard:

NOTICE: Connect test leads to the connector's backside. The connectors should not be disconnected from the ECM.

HINT: Voltage between the terminals of the ECM is kept constant regardless of the voltage of the A/F sensor.

(b) Connect the hand-held tester to the DLC3.

(c) Select "DATA MONITOR". Then select "A/FS B1 S1", and "O2S B1 S2" to display the monitors.

(d) Warm up the A/F sensor with the engine speed at 2,500 rpm for approximately 2 minutes.

(e) Keep the engine speed at 2,500 rpm and confirm that the display of "A/FS B1 S1" is as shown in the illustration.

HINT:

- The illustration may slightly differ from the display on the hand-held tester.

- Only the hand-held tester displays the waveform of the A/F sensor.

(f) Confirm that the display of "O2S B1 S2" changes between 0 to 1 V with the engine speed at 2,500 rpm.

2. INSPECT FUEL CUT OFF/RESTART RPM

(a) Increase the engine speed to at least 3,500 rpm.

(b) Use a sound scope to check for the injector operating noise.

(c) When the accelerator pedal is released, injector operating noise stops momentarily and then resumes.

Standard:

If the result is not as specified, check for DTCs. If a DTC is present, follow the repair procedures according to the DTC.

3. VISUALLY INSPECT HOSES, CONNECTIONS AND GASKETS

(a) Check for cracks, leaks or damage.

HINT: Removal or problems with the engine oil dipstick, oil filler cap, PCV hose and other components may cause the engine to run improperly. Disconnection, looseness or cracks in the parts of the air induction system between the throttle body and cylinder head will allow air suction and cause the engine to run improperly.

Be sure to check the areas indicated by the arrow marks.

If necessary, replace any damaged parts.

4. INSPECT FUEL CUTOFF VALVE AND FILL CHECK VALVE

(a) Disconnect the vent line hose from the fuel tank (see page 12-1 1).

(b) Connect the pressure gauge to the fuel tank..

(c) Fill the fuel tank with fuel..

(d) Apply pressure of 4 kPa (41 gf/cm2, 0.58 psi) to the vent port of the fuel tank.

HINT: It is necessary to check the amount of fuel in the fuel tank. When the fuel tank is full, the float valve of the fill check valve is closed and no air can pass through. (e) Remove the fuel tank cap, and check that pressure drops.

If pressure does not drop, replace the fuel tank assembly.

(f) Reconnect the vent line hose to the fuel tank.

5. CHECK AIR INLET LINE

(a) Disconnect the air inlet line hose from the charcoal canister.

(b) Check that air can flow freely into the air inlet line.

If air cannot flow freely into the air inlet line, repair or replace it.

(c) Reconnect the air inlet line hose to the charcoal canister.

6. INSPECT PUMP MODULE (PRESSURE SENSOR)

(a) Measure the power source voltage of the ECM connectors.

Standard

If the voltage is not as specified, replace the ECM.

(b) Measure the power output of the ECM connectors.

- Remove the fuel tank cap.

Standard

If the voltage is not as specified, replace the ECM.

- Install the fuel tank cap.

Location

Location

SYSTEM DIAGRAM

The emission control system is determined by the ECM based on signals from

various sensors.

...

Inspection

Inspection

1. INSPECT VENTILATION VALVE SUB-ASSY

(a) Install a clean hose to the ventilation valve.

(b) Check ventilation valve operation.

Blow air into the cylinder head side, and check that

a ...

More about Toyota Highlander:

Transfer RH bearing retainer oil seal (4WD)

REPLACEMENT

1. REMOVE EXHAUST PIPE ASSY FRONT (3MZ-FE ENGINE TYPE) (SEE PAGE 15-5 )

2. REMOVE EXHAUST PIPE ASSY FRONT (2AZ-FE ENGINE TYPE) (SEE PAGE 15-2 )

3. DRAIN AUTOMATIC TRANSAXLE FLUID

(a) Remove the drain plug, gasket and drain ATF.

(b) Install a new gasket and drain plug.

4. REMOVE TRA ...